Polyethylene is available in a number of grades according to its molecular weight including: LDPE (low density polyethylene), HDPE (high density polyethylene), UHMW (ultra high molecular weight polyethylene), and FDA Compliant grades.

Benefits of Polyethylene Plastic & Foam

Polyethylene foam is a durable, lightweight, resilient, closed-cell material. It is often used for packaging fragile goods due to its excellent vibration dampening and insulation properties. It also offers high resistance to chemicals and moisture.

Polyethylene foam is easy to process and fabricate. It has high load bearing characteristics that help manufacturers reduce packaging costs as they can use thinner and smaller amounts of foam yet still protect their products.

Other benefits of Polyethylene include:

- Closed Cell

- Very Lightweight

- Non-abrasive

- Easy to fabricate

- Non-dusting

- Superb strength and tear resistance

- Excellent shock absorption & vibration dampening properties

- Flexibility

- Impervious to mildew, mold, rot, and bacteria

- Resistant to water, chemicals, solvents & grease

- CFC free

- Odorless

- Excellent buoyancy

- Very cost-effective

- Excellent thermal insulation properties

If you have a need for a specialty grade version not listed here please let us know, and we’ll be happy to assist you.

Applications & Industries

Polyethylene Plastic & Foam products are regularly utilized in the following industries:

- Medical & Healthcare

- Aerospace & Marine

- Military and Defense Equipment

- Fluid Processing Equipment

- Construction Equipment

- Mining Equipment

- Architectural

- Material Handling

- Packaging

- Compressors

- Petrochemical

- HVAC

Please contact us today!

Products

Metallic

Non-Metallic

Custom Shims

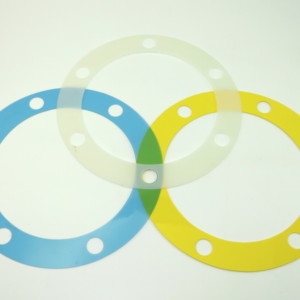

Gaskets

Materials

Metallic

Rubber & Sponge

Plastic & Foam

Cork & Cork-Rubber

Fiber & Paper

Felt

Adhesives

Specialty Gasket Materials

Capabilities

Die Cutting

Metal Stamping & Fabrication

Shim Manufacturing

Laser Cutting

Water Jet Cutting

PPE – Face Shields

Wire EDM

Prototyping